Refrigeration Methods for Dual Spiral Quick Freezing Tunnels

Dual spiral quick freezing tunnels utilize several advanced refrigeration methods to ensure efficient food freezing. These methods include:

-

Direct Refrigeration: In this method, refrigerants like ammonia or freon come into direct contact with the food, rapidly freezing it through evaporative heat absorption.

-

External Refrigeration Drive: The refrigeration system is positioned outside the tunnel. Cold air is transferred into the tunnel via a special mechanism, maintaining optimal temperatures.

-

Internal Refrigeration Drive: The cooling mechanism is housed within the tunnel itself, directly cooling the air around the conveyor belt to freeze the food.

-

Vertical Airflow Refrigeration: In this technique, cold air flows vertically from top to bottom, ensuring an even and efficient freeze of the food items.

-

Horizontal Airflow Refrigeration: Cold air is directed horizontally across the food, which is particularly beneficial for freezing items of varying shapes and sizes.

Each refrigeration method is designed to optimize freezing efficiency and ensure uniform results, tailored to the specific needs of food processing.

Key Features of the Dual Spiral Quick Freezer

-

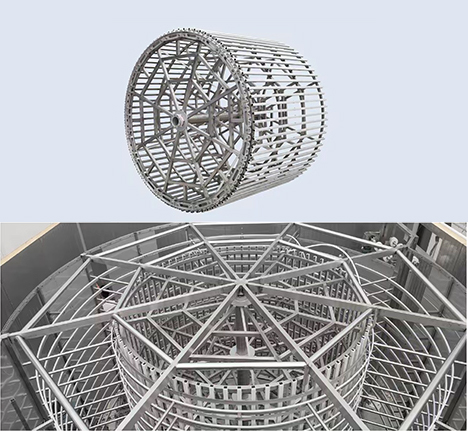

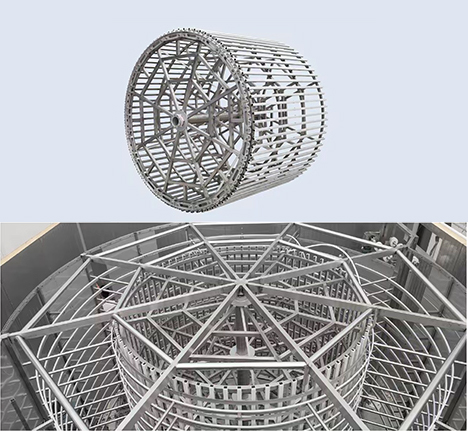

The dual drum structure of the freezer maximizes its capabilities, significantly enhancing the freezing efficiency.

-

Polyethylene protective strips support the drums and conveyor belts, providing high resistance to wear and tear, which extends the life of the stainless steel mesh belt. The advanced airflow design helps insulate the system, preventing frost buildup on the evaporator and increasing the time between defrosting cycles.

-

The dual spiral quick freezer boasts high resistance to elongation and abrasion, ensuring both longevity and stability.

-

An integrated conveyor belt monitoring system continuously checks the condition of the belt, preventing costly disruptions from unexpected malfunctions.

Technical Specifications

-

Structure: Dual Spiral

-

Control Panel: PCL touch screen control, made of 304 stainless steel

-

Drum Diameter: Ranges from 1620mm to 5800mm

-

Refrigerant: Environmentally friendly options

-

Mesh Belt Width: 520mm to 1220mm

-

Defrosting Methods: Water flushing or hot gas defrosting

-

Mesh Belt Material: 304 stainless steel/POM

-

Adjustable Freezing/Cooling Time: Frequency adjustable for flexibility

-

Inlet and Outlet Length: Each 500mm

-

Cleaning Methods: Mesh belt cleaning or ClP

-

Note: The specific details are subject to the equipment’s nameplate.

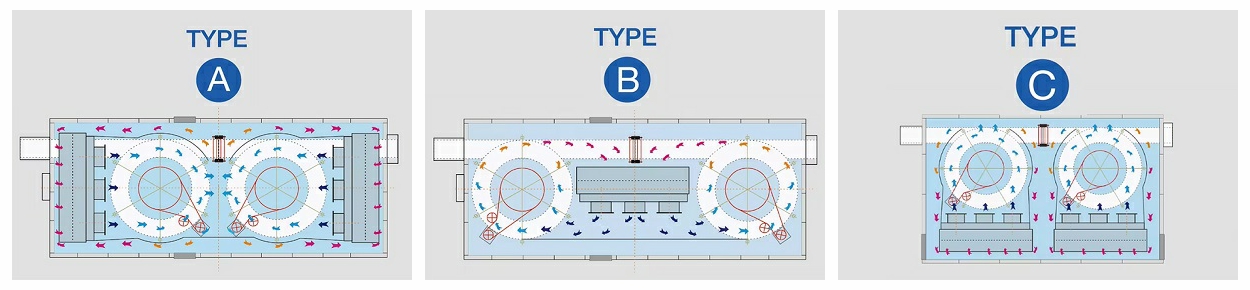

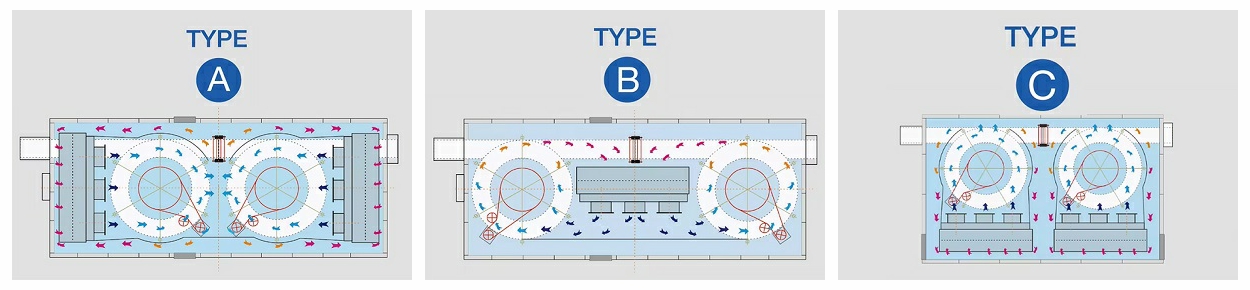

Available Structural Types

The dual spiral quick freezer can be configured in different layouts based on the relative positions of the cage and evaporator. These configurations are labeled as Type A, Type B, and Type C, providing flexibility depending on specific space and operational needs.

Applications

The dual spiral quick freezer is expertly designed for high-efficiency food freezing, suitable for rapidly freezing a wide range of food items such as dumplings, seafood, and vegetables. Its dual spiral mechanism allows for continuous freezing, boosting overall production efficiency. The system occupies minimal space and optimizes space utilization, meeting rigorous food hygiene standards. Additionally, the spiral design ensures uniform freezing, especially for foods that require precise temperature control due to their sensitivity to freezing times. With its modular construction, the freezer integrates seamlessly into automated production lines, enhancing processing capacity while ensuring consistent freezing quality.

Editor's Insight:

While the dual spiral quick freezer may involve a higher initial investment and require regular professional maintenance, its long-term benefits are immense. For businesses focusing on high-efficiency freezing and quality preservation, especially in large-scale food processing, the return on investment is substantial. The freezer's ability to handle large volumes of food with excellent freezing results makes it indispensable for enterprises with high freezing demands.

Small businesses may need to carefully consider the cost-to-benefit ratio, but for medium and large enterprises or those handling high-value foods, the dual spiral quick freezer is a superior choice for optimal performance and cost savings over time.