In the ice-making industry, increasing production efficiency, reducing energy consumption, and ensuring high-quality ice production are core concerns for businesses. With the all-in-one solution provided by CBFI, we successfully designed and built an 800-ton ice plant for our client with 16 CBFI block ice machines. These large block ice machines offer efficient and stable production capabilities, meeting the client's large-scale ice production needs. Below, we will detail the implementation process and results of this project.

Each CBFI block ice machine undergoes rigorous pre-shipment testing to ensure its performance meets the client's requirements. Our engineering team conducts multiple rounds of testing to ensure optimal cooling efficiency, energy consumption, and production capacity. Through precise adjustments, we ensure that each machine can be immediately operational upon arrival, eliminating the uncertainties that might arise from on-site testing.

After completing the pre-shipment testing, all 16 CBFI block ice machines are carefully packed and shipped. We provide specialized transport and packaging to ensure the equipment is protected from damage during transportation. By partnering with reliable logistics companies, we ensure that each machine is safely and timely delivered to the client's designated ice plant location.

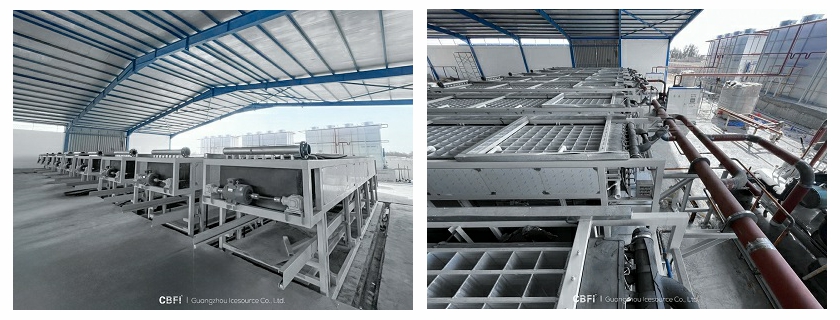

Upon arrival at the site, our technical team collaborates with the client to plan and layout the factory space. Each machine is positioned according to the client's needs, ensuring that equipment operations are not restricted by space limitations. The layout also includes setting up the necessary water, electricity, and cooling systems to ensure optimal working conditions for the ice plant.

The evaporator is a critical component of each CBFI block ice machine. The installation of the evaporator requires precise alignment with the design and layout of the ice plant. During installation, our professional team ensures the evaporator achieves optimal cooling performance, ensuring efficient and stable ice production.

As the core piece of equipment in the ice plant, the installation of the main unit is crucial. We adjust the installation according to the equipment's operational parameters and site conditions, ensuring seamless integration with other devices. Once installed, the main unit will work in tandem with the evaporator, condenser, and other components to achieve efficient ice production.

The installation of the evaporator condenser is essential for improving the overall system efficiency. By installing high-efficiency condensers, we optimize heat exchange, reduce energy consumption, and ensure stable ice production. Our technical team ensures that the condenser is perfectly installed and works harmoniously with other equipment.

After the installation of all equipment, our engineers conduct comprehensive production debugging to ensure each machine achieves the expected production capacity. During the debugging process, we monitor various system parameters such as water flow, cooling efficiency, and ice quality, ensuring smooth equipment operation. After rigorous testing, the entire 800-ton ice plant enters stable, efficient production.

Through this complete All-in-one solution for ice plants, CBFI provided the client with 16 highly efficient large block ice machines, successfully building an 800-ton ice plant. This solution not only increased production efficiency but also significantly reduced energy consumption, ensuring the quality and stability of ice production. We are confident that with CBFI's equipment and solutions, our client will stand out in a competitive market and achieve higher production efficiency.

Don't worry about pre-sales and after-sales issues. Our experienced engineering team and after-sales team will solve all installation, debugging, production, and maintenance problems related to the machines, ensuring a smooth start for your business. We are CBFI, Customer Benefit from Icesource.

Please contact us, and we will tailor the most suitable ice production solution for you.